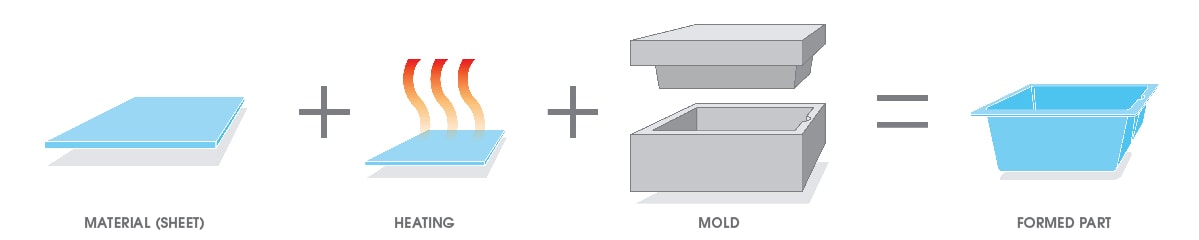

Thermoforming is a timely and cost-effective solution for heavy equipment enclosures, diagnostic housing, packaging, in-transit shipping solutions, and more. Plastic thermoforming is the primary manufacturing process Brentwood uses. Due to the high versatility of this manufacturing process, it is widely utilized for countless applications and methods to fit each customer’s project.

The two main types of thermoforming are vacuum forming and pressure forming. Each utilizes a different method to achieve the desired shape with varying finishes.

Vacuum Forming

Vacuum forming is the most common thermoforming method and is used for parts that do not need significant detail. For instance, medical trays, electronics housing, and hospital bed components are all parts that would be manufactured using the vacuum forming process.

Vacuum forming consists of heating a plastic sheet in an oven to a pliable forming temperature. The sheet is then stretched onto a mold, while vacuum holes and grooves in the mold remove the air from between the sheet and the mold. After being stretched over a mold, the formed part is cooled and trimmed to the desired size.

Pressure Forming

Pressure forming is a more advanced process that can produce components with intricate features, geometries, and textures that cannot be achieved using vacuum forming alone. Pressure forming is typically used to produce plastic enclosures and medical device components.

The pressure forming process is similar to vacuum forming in that a plastic sheet is heated in an oven to a pliable forming temperature and the air between the sheet and the mold is removed. However, pressure forming includes an additional top tool that adds pressure from above the sheet, forcing it against the bottom part of the mold as the air is vacuumed out via holes and grooves in the mold.

Our Thermoforming Process

Brentwood’s heavy gauge and light gauge capabilities utilize both vacuum and pressure forming techniques to fit each customer’s unique project. Our skilled designers work with each customer every step of the way, ensuring that all of their needs are met.

Have a project that needs thermoforming? Contact us today to get started on your thermoforming project.

0 Comments